Nail Gun Just Blows Air Problem [Reasons & 3 Ways to Fix]

Every household must own a nail gun. Nail guns are one of the most versatile power tools, both for DIYers and professionals out there. Many reputed and renowned brands manufacture quality nail guns. However, if you have one, you must be introduced to the problem of leaking air instead of nails from the nail gun.

Well, most nailers, even the ones from well-known brands, come with this problem. So, a nail gun that just blows air is a common problem. But to solve the problem, you do not have to go to an expert. You yourself can fix the problem.

Since a nail gun is supposed to be a heavy-duty tool, problems including blowing air are usual with it. You must be facing the problem too and that is why you are on this site. So, let’s discuss and let’s help you out of this problem.

Table of Contents:=>

3 Ways to Fix Nail Gun Just Blows Air Problem:

This happens when you press the trigger of the nail gun expecting to shoot nails instead it just blows air. It won’t be a mistake if said, air leaking occurs many times with a pneumatic tool. From the pumping valve of the pneumatic device, air leakage mostly happens. However, there are many other issues with the internal mechanism of a nail gun that cause this problem.

Generally, for shooting nails, pressing the button is important. When it is pressed, the produced air is bumped into the valve. Hence, the force takes the fire valve upwards. Therefore, technically it opens the primary cylinder sleeve enabling the air to pass the nail.

However, there are mainly two types of air leak problems that take place in most nail guns. They are given below.

Type 1. Air Leak From Top:

This is the head portion of a nail gun. It includes a rear exhaust port or exhaust vent. If your device is leaking air from this part then there are chances the O-rings of the nailer are worn. If the O-ring inside the machine dries out, it will fail to properly seal the fire valve. Consequently, when the button is pressed, it only releases the air causing a leakage. The air leakage also produces a hissing sound.

Generally, manufacturers insert O-rings inside the nail guns to seal the head valve surroundings. That is why they are mainly made of rubber. They counteract the air from getting into the valve while enabling the cylinder to function properly.

Type 2. Air Leak From Trigger:

Trigger valve can also be a reason for air leak. If it is around the trigger, you will feel it while operating the nail gun. It happens when frequent trigger pulling occurs. It causes wear or tear of any internal component related to the function.

Then again, if the machine is equipped with a defective trigger valve, nothing will work. In this case, you will not feel the air when it passes into and out of the trigger. However, when the trigger valve component is not properly running or cycling, this problem arises.

Nevertheless, a nail gun is manufactured with many other internal elements. They can also cause air blows from the nail gun. A leaky seal or top cap and a broken collar may also be the reason for the air leak. The broker collar helps to escape the air resulting in leakage.

Also, if the gasket inside the tool fails to seal between two pieces, air leakage will certainly take place.

Fixing Air Leak Problems From Nail Gun:

However, fixing air leak issues in a nail gun is not a big deal. You just need to find out first from where the air leak is occurring. Then you can get the part fixed on your own. Nonetheless, follow the solutions given below to fix this problem.

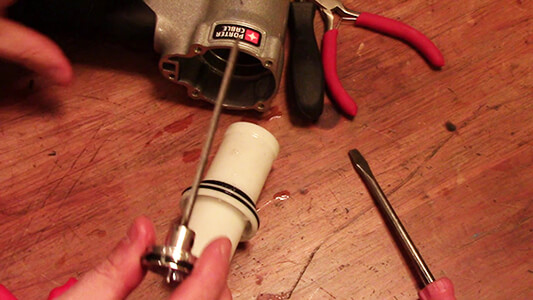

If the O-rings are the reason behind air leakage, then you can simply get new O-rings for your nail gun. Also, you can have a rebuild kit that matches your nailer model. Otherwise, you may not get the right O-rings you want to replace the worn-out ones.

Also, you can apply grease to your nail gun O-ring, stretching it on the firing valve. It will prevent the O-ring from drying out and causing air leak issues. This way you can also take care of the power tool. Grease application will keep the O-rings of the machine lubricated. It will also increase the ring’s lifespan.

You can also replace the nosepiece of the nail gun instead of the O-ring if the air is leaking out the vents. However, nosepiece replacing is a bit costlier than O-ring replacing. Therefore, it is your choice to select the solution that best narrows down the problem.

Again, if you detect the leakage from the piston head valve, you may need to replace it with a new one. To investigate the head valve, you need to dispel the top cap first. Then pull out the valve using a pick. Inspect it properly. If there are any damage, cracks, or wear signs, replace the valve installing the new one.

Interestingly, getting a repair kit can fix this problem quickly. Repair kits include every component you might need to reconstruct the inside of the nail gun. It can restore the nail gun to a new condition.

The moment you feel the air leak, stop the functionality of the nail gun. Then inspect the source of the air leak and fix it according to the it.

How To Fix Nail Gun Blowing Air Out The Back:

When there is a problem with the trigger valve, the nail gun blows air from the back. We have mentioned before how air leakage problems may occur from the trigger valve. However, mainly for the failure of the seals, it blows air out of the nailer back. So, you need to check the seals first.

If you do not have any problem with the seals, then it is surely the trigger valve. The worn trigger valves leak air. So, this is the main culprit here. So, you need to replace it. Unfortunately, there is a scarcity of trigger valves in the market.

Very few shops sold these working parts separately. Thus, you most probably need to deal with the whole trigger assembly. So, install an entire assembly of the trigger, to fic nail gun blowing air out the back.

3. Other Issues with Nail Gun:

Some other very common issues occurs with nailers. Depending on the problems, you can simply solve them without the help of any professional.

a) Nail Jamming Problem:

In most nail guns, this problem is obvious. Though now manufacturers are offering nail guns with a quick and fast jam release feature yet the problem might pop up. Well, the maximum time the fault is yours. If you use fasteners or nails that are damaged or the wrong size, then this problem will take place within no time.

However, the jam release feature is capable of solving this problem. Again, if the magazine screws are loosed this can also bring jamming problems. Then again, the damaged or chipped piston blade also creates jamming of nails.

Solution:

- Buy a nail gun that has a jam release mechanism.

- Make sure the screws are tightened enough.

- Check out the magazine screws every month.

- If the piston blade is damaged, replace it soon with a matched one.

b) Logy Nail Gun:

You can feel if the nail gun is effective enough or not. There are times when the mechanical device doesn’t offer sufficient power to work normally. Yet, it can drive nails. But you are not satisfied with the performance.

Solution:

1. Increased Air Pressure in The Pneumatic Tool:

A pneumatic nail gun doesn’t require a great deal of air pressure to function practically. It only requires an air compressor with a low pancake volume. However, the smaller compressor takes time to build up the required air pressure. In the process, the air pressure can fall because of the leaks. So, in this situation, raising the air pressure can fix it well.

2. Cleaning and Lubricating:

Producing dust and debris is common while using a nailer. However, the dust may enter into the nail gun and create problems in the internal movement of the components. So, frequent cleaning and lubricating will keep the internal parts of the tool smooth. It will also prevent sluggishness.

c) Inappropriate Air Pressure Adjustment:

As we mentioned before, a pneumatic nailer generally runs with an air compressor. The pressure range between 70 to 120 psi is optimum for the functioning. However, if the nailer creates pressure higher or below this range, an air pressure problem emerges.

Moreover, the improper air pressure adjustment will create a blank shot of nails.

Solution:

- Set the exact required pressure for the air compressor required in the pneumatic nailer.

- Check the user manual of the tool to be sure of its desired pressure.

d) Other Issues Regarding Repair Maintenance:

There are some common defects that are found in a nail gun. Nowadays, nail guns are more improved and developed. However, the intricate design may lead to some defects given below.

- The nail magazine might get twisted

- The loader spring might twist as well or weaken, or be torn

- Narrow down the guide channel

- Leaking air around the framing nailer trigger

- Nailers shooting blanks

- Trouble with movement by produced dirt or deposited grease

So, these are the common problems. However, anything happens to your nail gun, there is always a solution. Diagnosing the problem is the first and foremost thing to do. After that, according to the problem you can replace, remove, or fix the damaged part.

However, what will help you the most is the routine care of your nail gun. A nail gun is not that high-maintenance. Cleaning the external and internal parts of the tool once in a or two weeks will keep the nailer damage-free. Also, oiling and adding lubricants to the moving parts of the nail gun will keep the part smooth and always ready to slay.

FAQs:

Question: How do you fix a nail gun that won’t fire?

Answer: Sometimes it happens when the nail gun stops firing. So, to fix the problem, you need to diagnose it. First, check the front end of the nail gun. Look if there any jammed nails. If so, then clear the jam. If there isn’t any problem in the front end check out the back part of the device.

Pull off the back plate of the nailer and inspect the O-rings of the tool. Also, supervise the plunger shaft and plunger O-ring to find anything foreign. If any problem is found with the O-rings, you can replace them. Or to prevent the problem the nailer needs to be regularly oiled.

Question: What to do if your nail gun jammed?

Answer: Even though more than 90% of the nailers support a system that offers a quick jam release. So, if your nail gun gets jammed you can simply release the jam. However, to operate the feature, first, you need to stop the air supply. In the case of a pneumatic nail gun, disconnect the electrical support.

Again, for the cordless ones, shift the battery. When you are done doing this, press the push button and release the magazine. Then, again, release the latch above the shooting nose. Now, to find the dislocated nail that is creating the jam, open up the front cap.

When you find the nail, remove it. So, this is what you can do if your nail gun is jammed. In the exceptional case, if your nail gun doesn’t boast a quick jam release feature, then you should go for a wrench. Make sure you bring the proper wrench with the perfect size that will help to remove the jam.

Using the wrench, simply loosen the screws to open the head. Find the blocked nail and remove it. Then tighten the screws in their places again closing the magazine.

Question: Why is my framing nailer leaking?

Answer: There are many reasons a framing nailer fails and causes air leaks, and we have mentioned them already. It can be the deteriorated O-rings, worn or arrested driver bumper, trigger valve, cylinder seal leakage, or anything regarding the function of the nailer.

Last Updated on June 19, 2025 by Rogers Weber

[As an Amazon Associate I earn from qualifying purchases.]